FUNCTIONAL & FASHION FINISHING ON

DENIM FABRIC

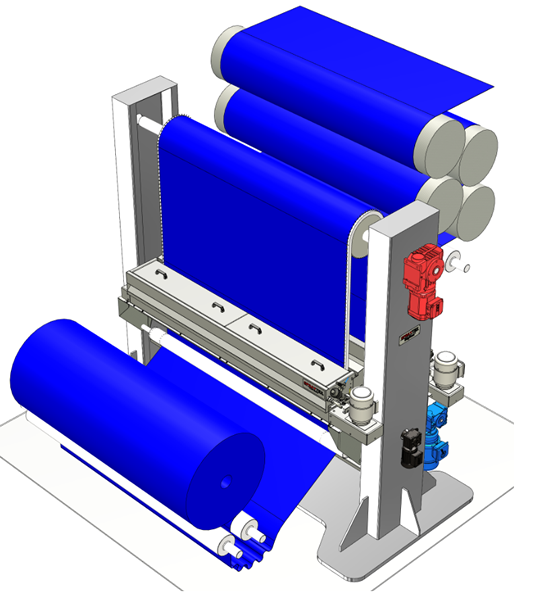

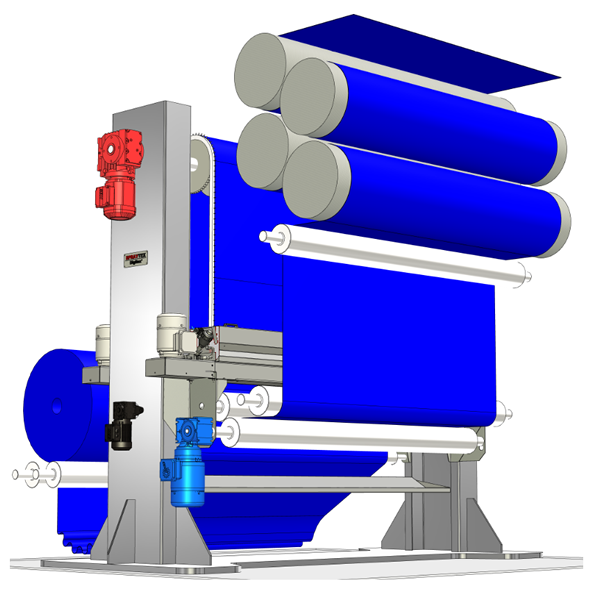

The Spraytex-Coater® applicator can deliver coating on denim in an excellent, fast, and efficient way. The spray application aims to keep indigo darker for longer with a natural shiny Look – “fresh” and clean in the greenest way possible, only to obtain a good homogeneity in the non-contact application.

Its denim finishing application is entirely different from the traditional resin finishing using large quantities of water and chemicals. The resin application by the Spraytex-Coater® effected contactless and without streaks by the spraying of rotating sprayers. The resins only applied twice on the face of the fabric, saving chemicals and water significantly.

Some desired feactures:

“Stay longer dark” – one wants the denim to fade, but don’t want it to fade too fast and not into an unnatural color;

Clean Look – “fresh” – confortable not hard and stiff;

“Polishing” – Natural Shiny Look.

In contrast to the conventional technology of applying with the foulard vat, where the chemical liquor’s application into the fibers carries out by squeezing through two or more pairs of rollers, that means both sides of the fabric are treated. The resulting material is hard and stiff; the acrylic resin’s daily contact against the skin could cause allergic effects.

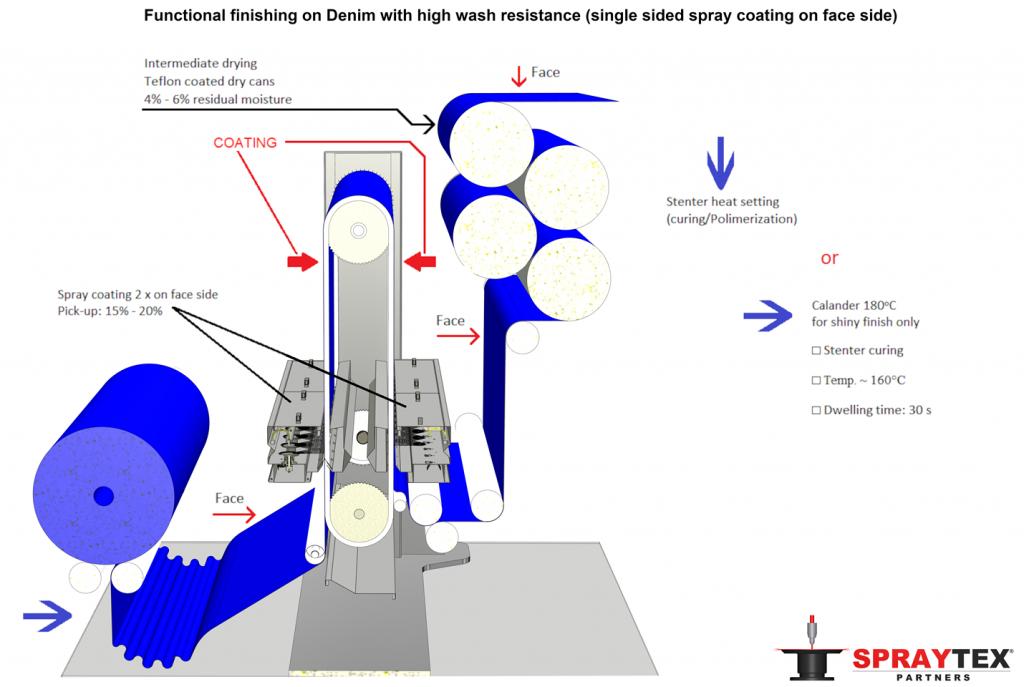

Functional finishing on DENIM with high wash resistance (single sided spray coating on face side):

2 x or 4 x Spray applications on face side only:

Pick-up: 15%– 20%;

Intermediary drying: 4% – 6%;

Calander: 180°C.

In contrast to the conventional technology of applying with the foulard vat, where the chemical liquor’s application into the fibers carries out by squeezing through two or more pairs of rollers, that means both sides of the fabric are treated. The resulting material is hard and stiff; the acrylic resin’s daily contact against the skin could cause allergic effects.

Spray coating means functional finishing on the DENIM fabric with a minimal application between 15%-20% pick-up. Contact-free applications mean:

BENEFITS

Technical/Economical

Practical

Ecological