SPRAYING CHEMICALS APPLICATIONS

Woven + Knitted Fabrics – Non-Woven – Biomaterial fabrics – Digital Printing – Denim Finishing – Technical textiles

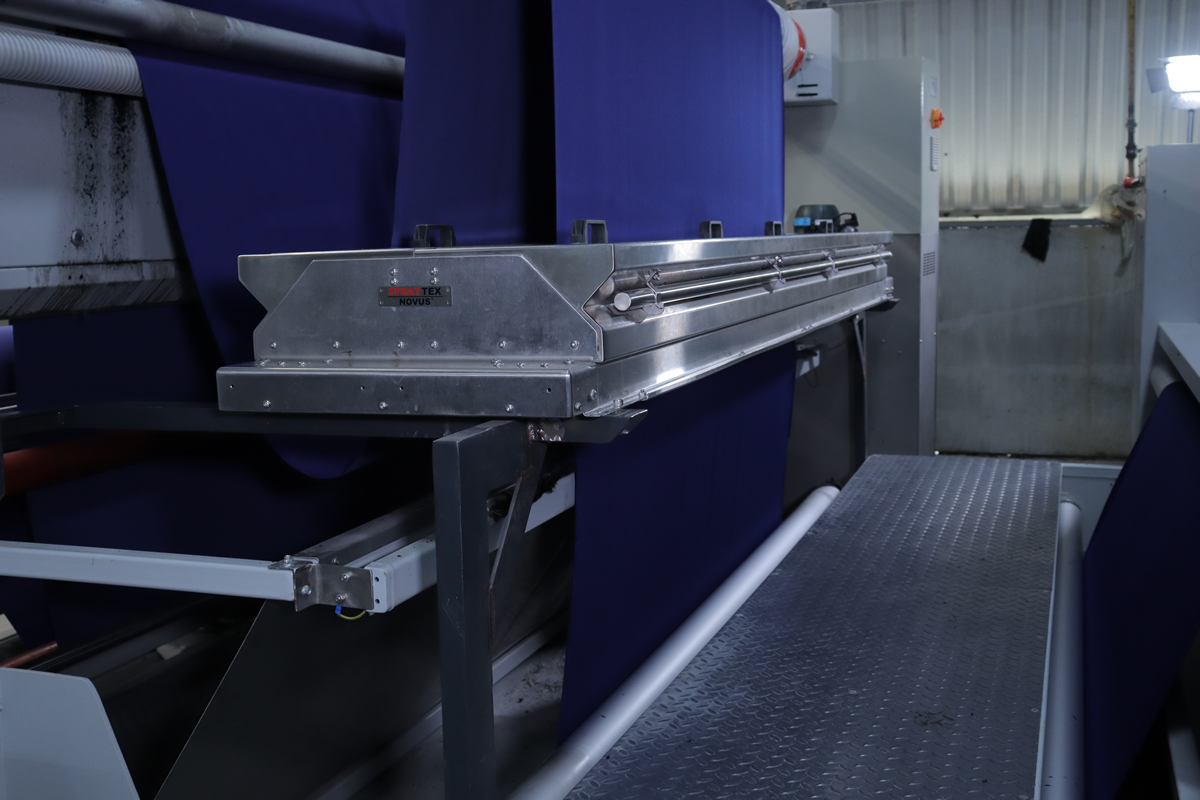

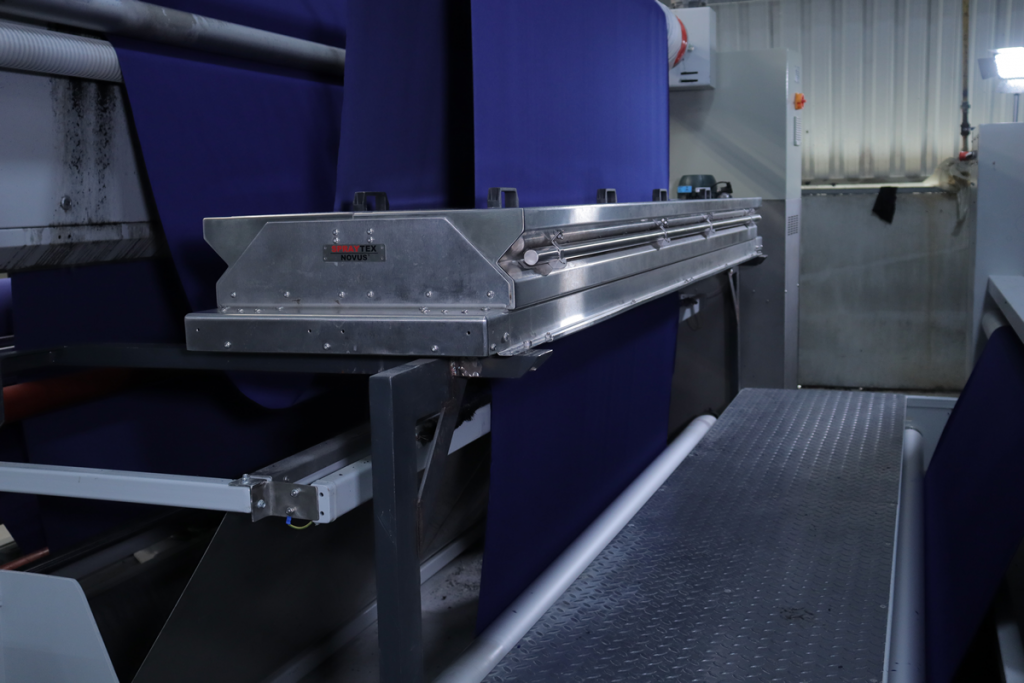

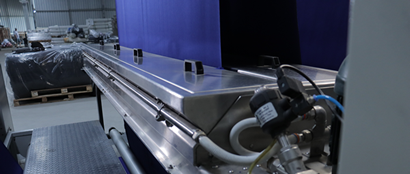

SPRAYTEX® Spray Unit

What we do?

We develop and manufacture rotary spray systems suitable for Moistening, Functionalization and Coating – textiles, nonwoven, bacterial based materials such nanocellulose, plastic free textiles, among others.

In the last five years, Spraytex Partners installed more than 130 spray units for different textiles process applications. SPRAYTEX® develops and helps user solve spray applications problems.

How we do it?

The know-how of spray technology for non-contact applications is based on suitable auxiliary chemicals, application methods, and their interaction.

How we got the know-how?

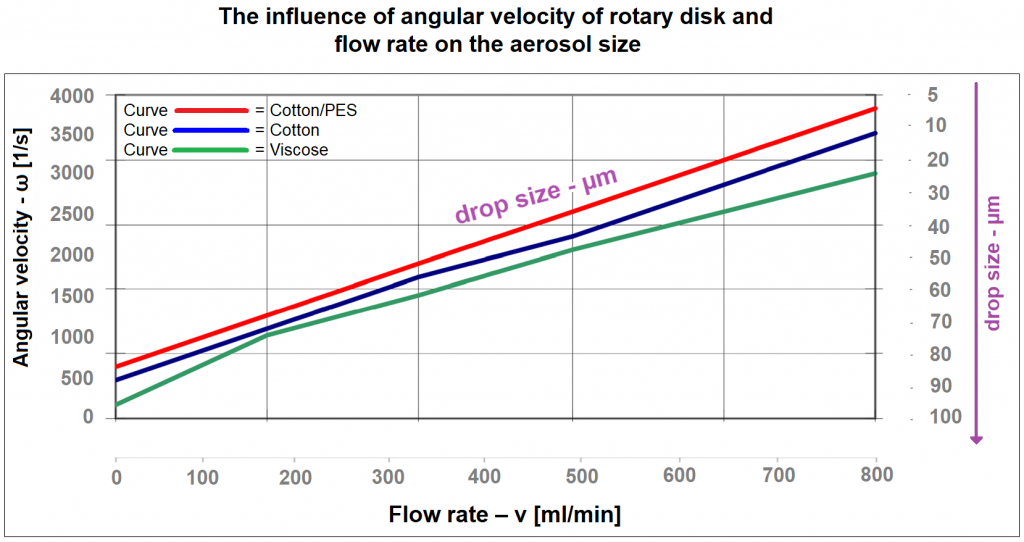

The effective optimization of the spray parameters, the exact relationship between them (angular velocity of the rotor disc, angular spraying, aerosol size and impact speed) is obtained after many years of experience, consuming time, and money. The secret sauce is that expertise in innovation has resulted in an advance in finishing, coating, and other applications.

How we got the know-how?

SPRAYTEX®️ applicators provide a solution for the homogeneous spraying of water or chemical baths – without contact – one-sided or twin-sided to the surface on moving textile materials (fabrics and knits, non-wonen and technical textiles).

TEXTILES + NON-WOVEN SOLUTIONS

A minimal application with rotary spray technologies allows significant savings in water and energy, particularly drying energy. In addition, the amount of residual liquids is reduced, which reduces disposal costs.

Please get in touch with us for detailed information about the installation of Spraytex Applicators in your textile machine.

What we do?

SPRAYTEX® system applies moisture or functional chemistry that is only needed one-sided or twin-sided into the goods, e.g., water repellents, softeners, anti-bacterial, anti-immigrants, material dispersion in water (nano particle size). Just applying as little possible and as much as necessary. Less is more!

Coating is a crucial technology for innovative processes in textile finishing, non-woven, biomaterial fabrics and technical textiles.

Coated fabrics place high demands on the flexibility of the application systems. The coating can be applied to the thinnest layers for functionalization to virtually any textile substrate. The spray technology ensures optimal coating quality regarding energy consumption and resource conservation.

The amount of chemistry and the subsequent drying can be reduced significantly. The applications of coating processes are wide-ranging and often include chemicals of various rheology’s.

How we do it?

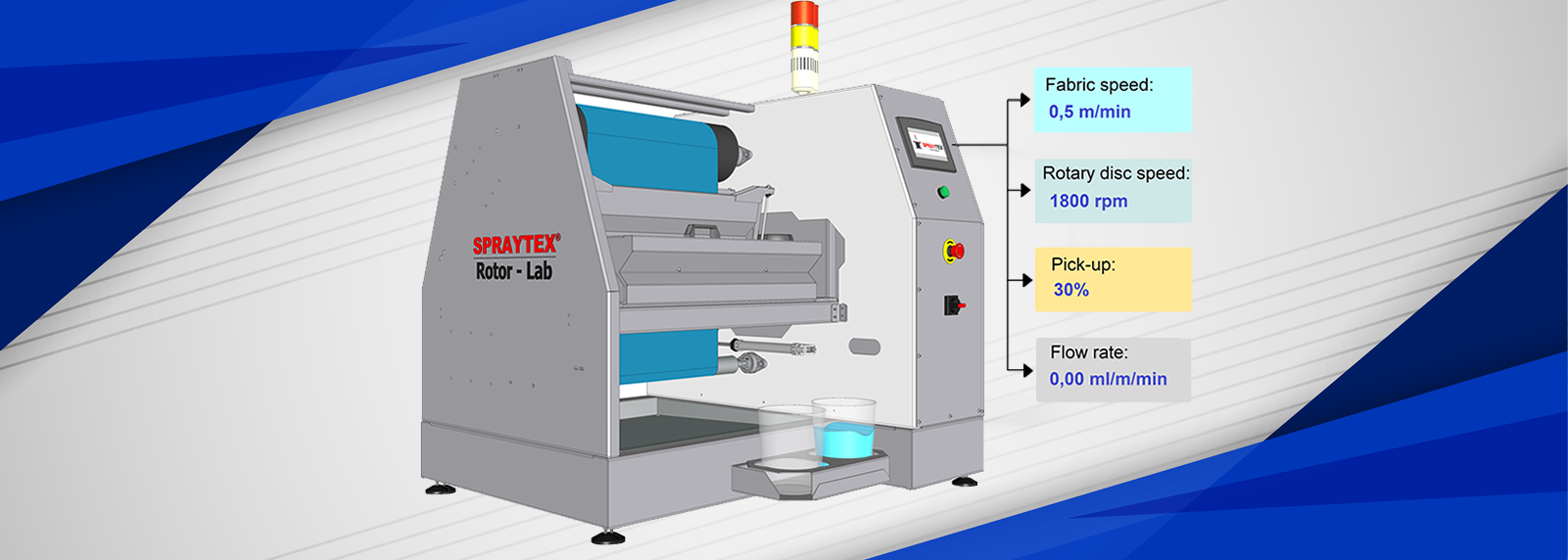

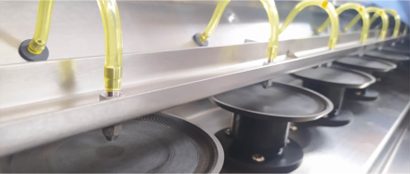

Our technology is based on rotating spray discs; a homogenous stream of the finest micro-droplets is generated at high speed to give the fabric its individual properties with precisely defined accuracy. The application quantity can be controlled with exactly reproducible results.

Transfer efficiency can be evaluated based on the throttle valve flow rate and the weight of the deposited material onto the material target. For coating applications, volume flow rate combined with liquid distribution and droplet size across, and kinetic energy are critical parameters.

How we got the know-how?

The effective optimization of the spray parameters, the exact relationship between them (angular velocity of the rotor disc, angular spraying, aerosol size and impact speed) is obtained after many years of experience, consuming time, and money. The secret sauce is that expertise in innovation has resulted in an advance in finishing, coating, and other applications.

Our patented Rotor Spray System (European Patent EP 3 011 098 B1) – Method for the controlled application of a dyeing liquor to a yarn, yarn bundle, or a textile web) represents a significant advancement in spray application technology. The core of the Spraytex-Applicator is the rotor spray device, its drive system, and the feeding method of different chemicals in the distribution rotor disk, which opens the door to new applications in coating textiles, non-woven, and paper not before possible. The patent is owned by us and our partner in Germany.