PRE-TREATMENT OF KNITS AND FABRICS IN THE PRE-TREATMENT FOR DIGITAL PRINTING

MINIMAL APPLICATION = LESS IS MORE IN THE APPLICATION OF CHEMICALS TO TEXTILES

SPRAYTEX-NOVUS® design to meet the high pre-treatment demands for digital printing. The equipment applies chemical baths with synthetic or semi-synthetic (low viscosity) thickeners. Application is non-contact – without streaks or striping of the fabric or knit, twice only on the right side of the textile substrate. The applicator allows adjustment of the spray width.

Minimal Application controlled through spray with rotors applying quantity only what is necessary and as little as possible.

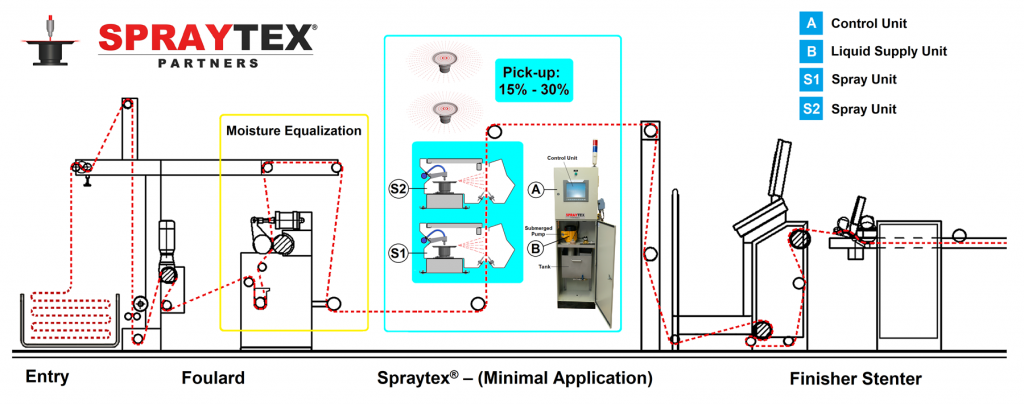

Spraytex’s equipment installed at the entrance of stenter – one-sided application with two spray units.

The pre-treatment (coating) with migrations inhibitors is one of the most critical steps in functionalizing surfaces for digital printing to produce high-quality properties.

Compared to the foulard, which applies with high pick-up, rotor spraying is a gentle, non-contact finishing, which is of the utmost importance for knitwear. These reasons require a move away from traditional application systems towards new, efficient, and highly accurate non-contact application methods for pretreatment for inkjet printing.

BENEFITS