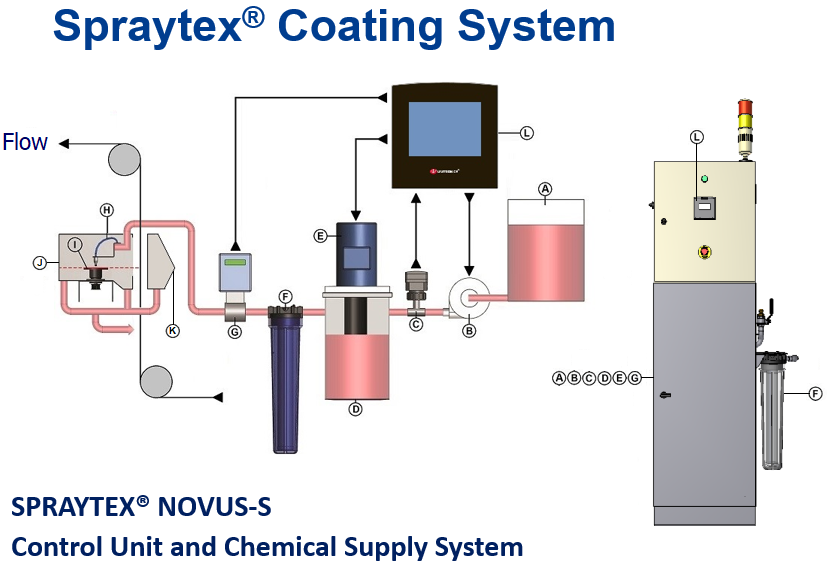

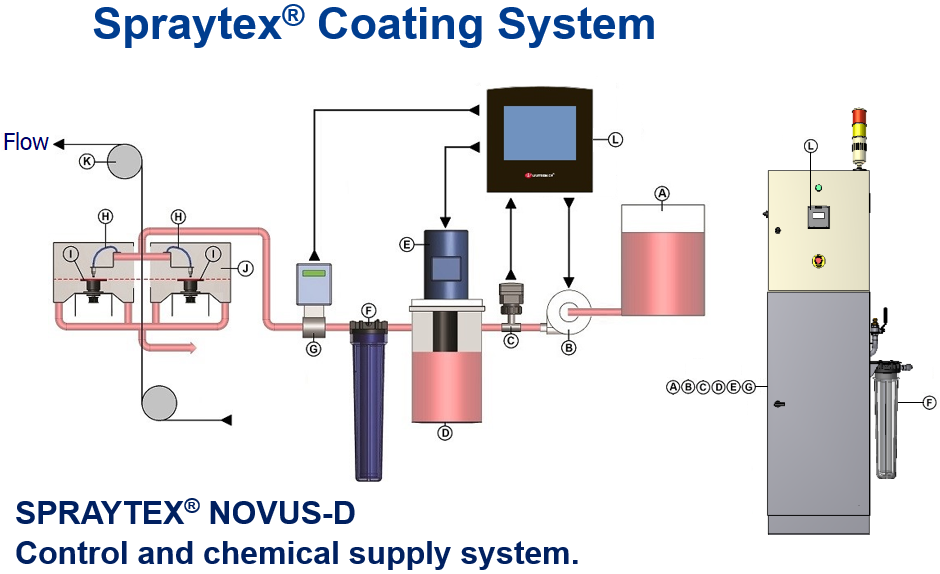

PRODUCT: SPRAYTEX®-NOVUS

CHEMICAL AUXILIARIES’ APPLICATIONS ON WOVEN AND KNITTED FABRICS – NON-WOVEN – TECHNICAL TEXTILES – BIOMATERIAL FABRICS

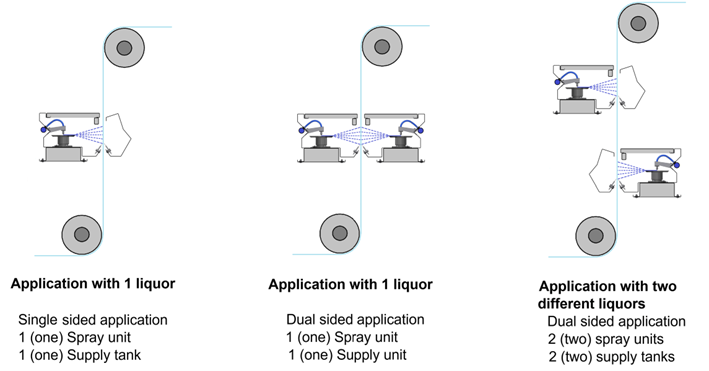

The Applicator SPRAYTEX®-NOVUS apply chemical auxiliaries: contactless, one-sided, or twin-sided uniform, streak less on the surface of woven, non-woven, technical textiles, biomaterials fabrics due to multiple overlap of the spray fields.

This applicator can be incorporated in a textile production line, such as a stenter frame, coating range, drying range. It also works as a standalone to apply chemicals in textiles, preparation, and grounding for digital printing, non-woven, denim finishing, biomaterials fabrics or technical fabrics, such as: seat covers, curtains, sail clothes, mattress fabrics, among others.

It is possible to spray a minimal metered application between 5%-40% of chemicals auxiliaries. Comparing with the impregnation foulard’s application of 80-100%, the drying costs are substantially reduced. Due to the minimal application of pick-up on the fabrics, less water or chemicals auxiliaries will have to be dried, allowing an increase the production speed of retrofitted range or stand-alone machine improving the productivity.

Additional benefit due to the contactless application the fabric stresses is dispensed from squeezing excess liquid.

APPLICATIONS POSSIBILITIES VERTICAL SUBSTRATE PATH

BENEFITS

Technical/Economical

Practical

Ecological

Technical Information:

Electrical power source: 380 – 400 VAC/60Hz/3ph or 380 – 400 VAC/50Hz/3Ph

Spray range: different configurations for woven, non-woven and knitted goods are available in working widths of 1000-5700 mm.

Spray application rate: 50 – 3800 ml/meter/min