TEXTILE FINISHING

APPLICATION TECHNOLOGY OF SOFTENERS IN TEXTILES

FOULARD VS. SPRAY TECHNOLOGY

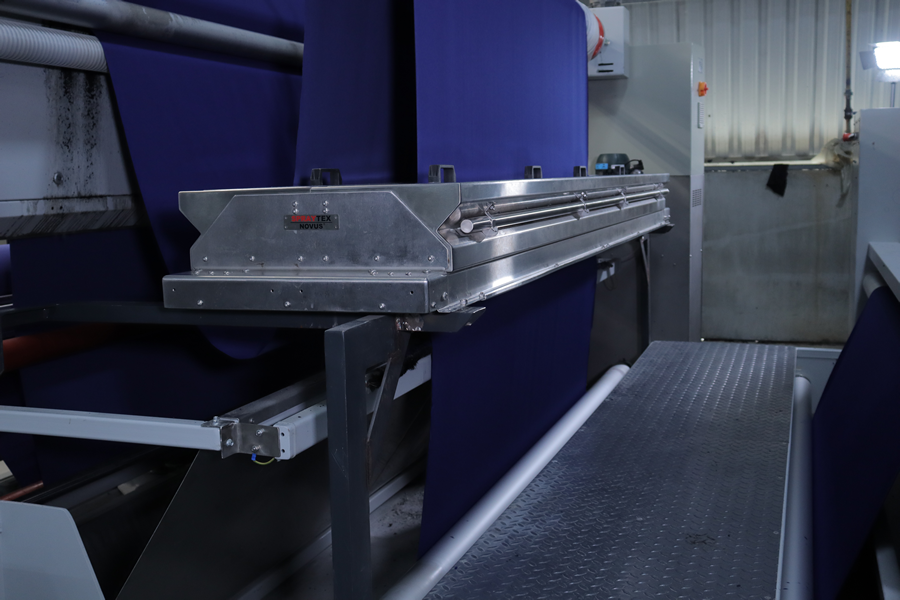

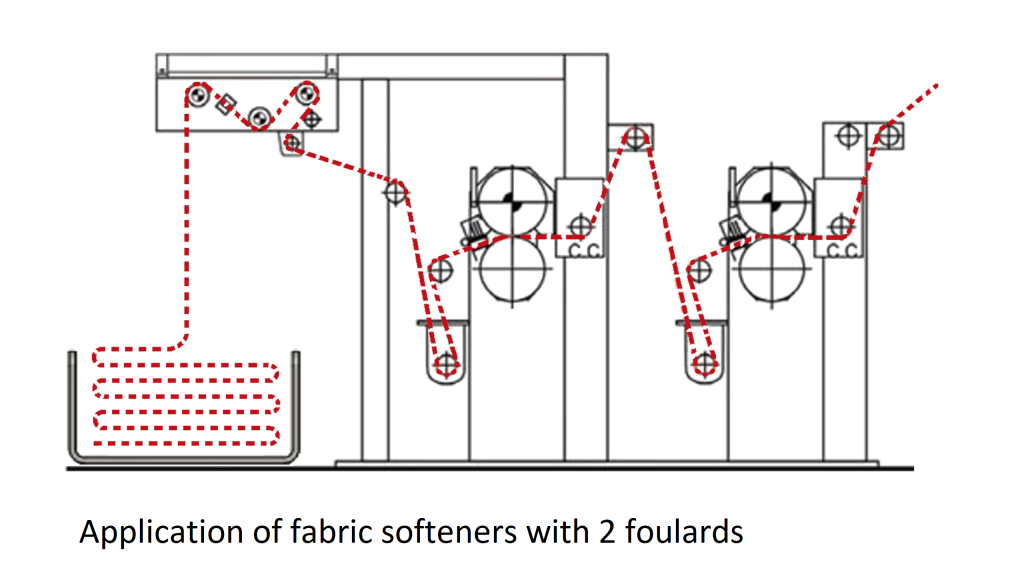

SOFTENER IMPREGNATION WITH 2 FOULARDS

The most common method of impregnating chemicals in knits and fabrics (immersion) uses two pads. The material squeezes at the first pad’s outlet for the bath’s removal and equalization; the fabric softener is applied on the second pad.

Benefits:

Disadvantages:

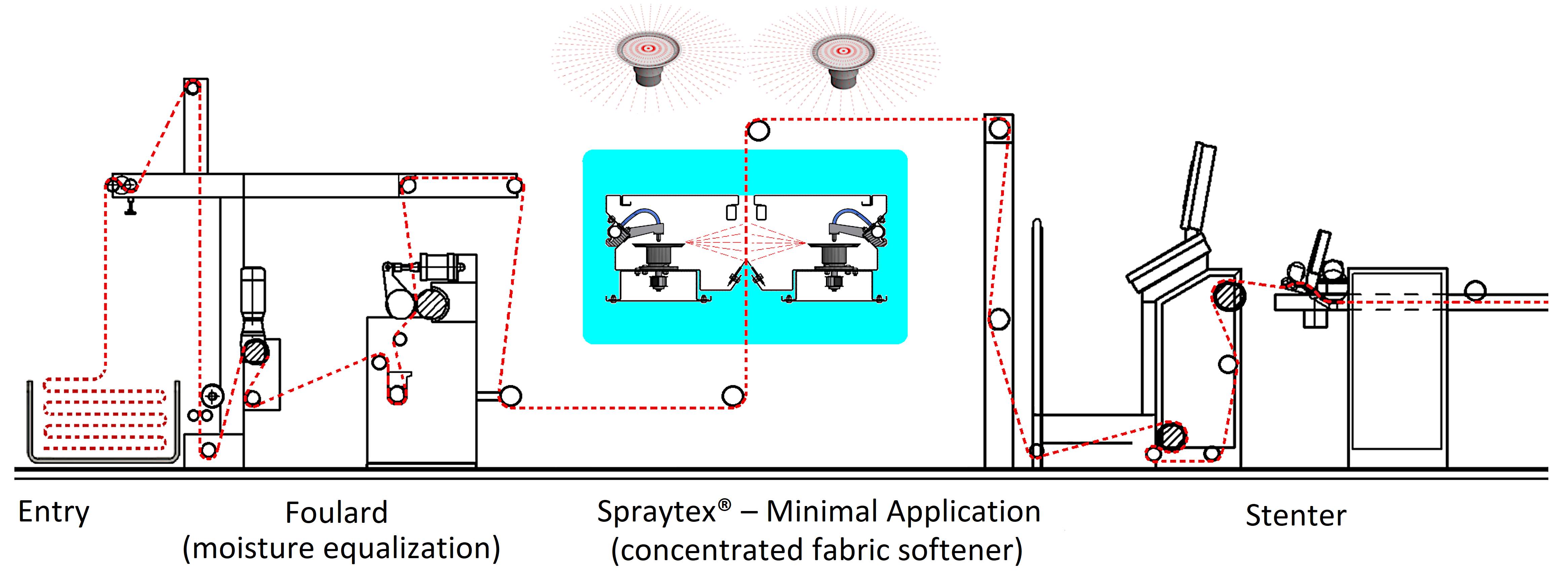

HYBRID SYSTEM – FOULARD VS. SPRAYTEX

Optimized process: pre-equalization of moisture on the impregnation pad and then applying the concentrated softener with the SPRAYTEX® applicator. The chemical bath (softener) is covered with spray technology – without physical contact – on the surface of the textile material, with penetration into the fibers. Penetration is a function of the rotary disc’s angular velocity (rpm). This alternative allows you to apply as little as possible and as much as necessary. Less is more!

Benefits:

FINISHING STENTERS (ENTRY AND OUTLET)

SOFTENERS AND CHEMICAL AUXILIARIES